White Ink printing is a big deal in UV printing industry now because it brings high profits for sign, advertising, decoration and many other printing applications. And one of the great things is that you can print colorful images on dark materials with white ink.

Main printing solutions of white ink in UV printing

Print white ink only

Used as colored inks, this method is used in the printing of design of only white. For instance, print white images on transparent acrylic, print white characters on black materials.

White ink + Colored inks

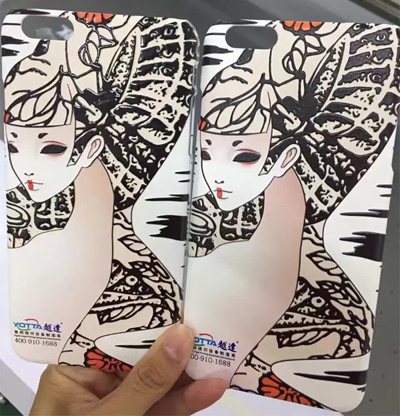

Similar to the above situation, this solution is usually used to print dark materials. In this case, white ink printed as a layer underneath. Colored inks printed on the top of white ink. This is one of the most important applications of white ink. Because it is more adaptable to the printing of dark and transparent materials. By printing multilayer white ink underneath, it can achieve extremely realistic relief effect, creating a sense of three-dimensional.

Colored inks + White ink + Colored inks

In this case, white ink printed as a layer between two colored ink layers, for day/night backlit applications. In UV flatbed printing application, this method is usually applied to transparent materials. Take glass printing as an example, you can see the plane effect on the other side of the glass print, and the printed surface builds the relief effect.

Common problems of white ink printing

When printing white ink, it may be more prone to plugging printhead. This is related to the titanium dioxide, the main composition of white ink. Due to this main composition, white ink is easier to delaminate and form precipitates. However, the nozzle aperture of inkjet printer is very very small. When the white ink is stratified and precipitated, the print head is easily blocked.

Besides, the problem “white ink printing is not white enough” may occurs, this is also caused by the stratification and precipitation of white ink. After sedimentation caking, small particles in white ink will reduce, thus weaken the printing effect of white ink. The smaller the particles, the lighter the white color printed out.

In response to these problems, YOTTA has introduced white ink mixing system for its UV printing machines, which effectively prevents white ink precipitation, further to prevent nozzle clogging and bad white ink printing effect from the source.

White ink printing is widely used, but white ink printing is an optional function. It can be selected according to the actual application. In general, It is used most frequently in sign printing, advertising printing and decorative printing.

We provide remarkable digital UV printer with white ink capability and professional printing solution for various industries, including UV flatbed printers, hybrid printers (flatbed and roll to toll), roll to roll printers. Welcome to contact us for more details.