Description

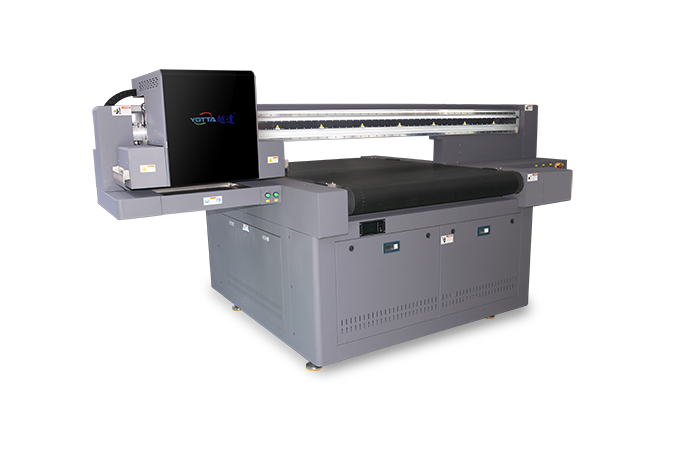

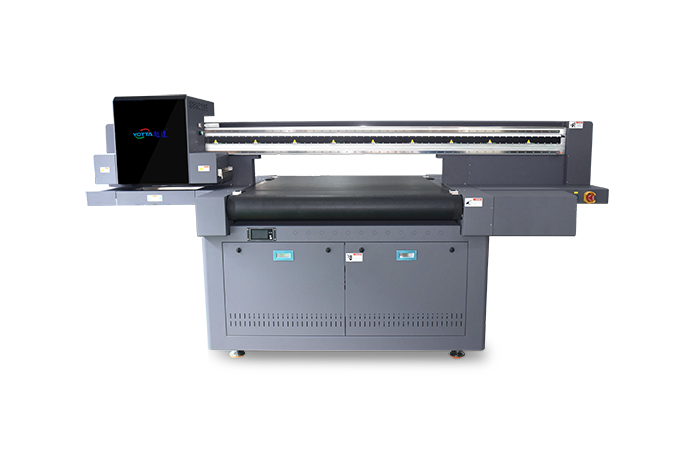

YOTTA YD-1319 produxtion line high-speed visual UV printer is a perfect combination of visual positioning system and guide belt transmission technology, taking into account both high efficiency and high precision of printing. The equipment supports automatic loading and unloading and scanning-while-printing functions, realizing unmanned operation of the entire process and greatly improving production efficiency.

What can you do with yotta's uv printers?

What do you want to do ?

In order to create beautiful designs, or start your own business and realize your ideals, or make money…, Whatever it is, keep doing it please!

what effect do you want?

The printing effect is clear and vivid, the image is waterproof, sunscreen, wear resistance and do not fade. The machine operation is simple and convenient, easy-to-use. The speed of printing image is so quikly that it fully conforms to the printing industry standard. Working stably and instant provision.

What should you do next?

First, inquiry us for more details. Second, you can request a free print samples. Third, welcome to visit and communicate with us in our company. Of course, you can also give us an order directly if you have known us well before.

Wide application:

Home decoration industry: ceramic tiles, individual furniture, backwall gound, cupboard, home appliance panel…

Advertising industry: billboard, banner, PVC card, KT board, signage, PP board…

Glass industry: art glass, glass partition, glass sliding door, glass background wall, frosted glass…

Packaging industry: paper, wooden, metal, PVC, leather packaging printing…

……

Printing materials: glass, phone case, backwall ground, ceramic tiles… more details about free print samples, please contact us now.

Advance features of YD-1319 UV Printer Visual Positioning

1. Ricoh Gen6 print head

Imported from Japan, Ricoh Gen6 print head is the high level print head in the industry. Stronger ink compatibilityMaximum firing frequency 50KHZ, minimum ink drop 5 PL printing speed 24-120 ㎡/h. Stronger ink compatibility Besides, the lifetime of Ricoh printhead can be longer than 5 years if it is well maintained.

2. Servo motor

Servo motor, high-precision servo motor, fully guarantee the high precision of the equipment rotation and reduce the occurrence of PASS

3. Automatic thickness measuring

YD-1319 automatically measure with senses thickness of media, which eliminate the procedure that we measure thickness by ourselves, avoiding damage caused by human error. It is very efficient and accurate.

4. Automatic anti-collision function

The new anti-collision structure is sensitive and pratical, when coming across with collision ,the print head carriage will stop automatically in order to protect printheads and the whole machine from damage.

5. The suction platform

The suction platform has an area-controlled suction function with six new ABCDEF areas, which use more flexible layout increased application surface for different formats of printing media.

6. New added ink tank level display system

Convenient to check the ink level of the main ink tank in a timely manner with integrating vision and hearing, which is convenient and practical.

7. Ink thermostat system

This system helps the printer keep ink viscosity in low temperature. It can adapt to ambient temperature automatically, ensuring high-quality printing.

8. Double negative pressure system

Ultra-high stable dual negative pressure system, white varnish color independent negative pressure system to make the negative pressure more accurate.

9. Multi-color printing

The color options include CMYK, Lc, Lm,W,V, and it also allows white ink and varnish printing. Therefore, the uv printer visual positioning can achieve 3D, glossy effect etc, meeting the special printing needs of various industries.

10. UV LED curing system

YOTTA’s YD-1319 employs UV LED light for ink curing system, can help ink dry quickly and save more energy. It is environmental, effective, and has a long using life.

11.The silent drag chain

avoids signal interference, reduces signal wear and extends service life. Compared with similar machines and equipment, the working sound is smaller and the noise is reduced by 20%.